Downloads

Download

This work is licensed under a Creative Commons Attribution 4.0 International License.

Article

Research on Abnormal Starting Noise of Efficient Engine Caused by Abnormal Combustion Noise

Feng Huang 1, * , Xiaochun Zeng 1, Xili Wang 1, Xinqi Qiao 2, Yi Wang 1, Liang Fang 3, Yunhua Zhang 3, Dengcheng Liu 4, and Yonghong Deng 4

1 Jiangling Motors Co., Ltd., Nanchang 330001, China

2 Mechanical and Power Engineering College, Shanghai Jiao Tong University, Shanghai 200092, China

3 Automobile College, Tongji University, Shanghai 200092, China

4 Nanchang Automotive Institute of Intelligence & New Energy, Nanchang 330052, China

* Correspondence: fhuang6@jmc.com.cn

Received: 20 February 2024; Revised: 7 April 2024; Accepted: 9 May 2024; Published: 22 May 2024

Abstract: An abnormal noise problem was reported in a pickup truck equipped with a 2.0 L efficient engine during start-up. The noise was reproduced by the engine anechoic chamber bench for further analysis. NVH test (conducted through audio playback and signal filtering) showed that the noise had a signal of 1–3 kHz. Analysis through cylinder-by-cylinder oil-cutting method found that the abnormal noise completely disappeared after the fourth cylinder was cut off, indicating that the noise was related to the combustion of the fourth cylinder. The combustion characteristics of each cylinder were then analyzed in the starting condition through the Kibox combustion analyzer. The noise appeared after the first fuel injection of the fourth cylinder, and the maximum pressure rise rate was 42 Bar/°, confirming that the abnormal noise was combustion noise. Further tests on the physical fuel injection signal of each cylinder found that the fourth cylinder only had the main injection signal with no pilot injection signal. Further analysis of the synchronization signal recognition method of the model and the underlying logic of the fuel injection program showed that the synchronization signal was recognized for the first time in the starting process after the calculation moment of the 4th cylinder pre-injection program, resulting in the failure of the pre-injection calculation. Finally, the bottom fuel injection interrupt program was pushed back (60° to the crankshaft angle), ensuring smooth injection of the 4th cylinder pilot injection in the starting working condition, thus solving the abnormal noise without impacting engine performance.

Keywords:

abnormal noise combustion noise rate of pressure rise synchronization signal fuel injection interrupt1. Foreword

The reliability of engine starting and NVH (Noise Vibration Harshness) performance are crucial for the normal operation of a vehicle. The starting performance of engine after a long drive and at low-temperature conditions are key in the development of a vehicle. Good starting sound quality and small vibration levels are associated with a good driving experience. The resistance of compressed gas in the cylinder and the frictional resistance between the moving parts of the engine and its accessories should be overcome during the engine start-up. The fuel injection quantity during engine start-up is about 4–5 times higher than when the engine is idle, indicating a harsher combustion environment and stronger excitation at the source, which results in NVH problems during engine start-up.

Earlier studies have assessed the diesel engine combustion noise and recommended increasing pilot injection to reduce combustion noise. Besides, studies have reported the principle and influencing factors of diesel engine combustion noise [1–8] and the specific control parameters, such as common rail pressure, pilot injection quantity and interval, main injection advance angle, EGR rate. Miller cycle engine produces combustion noise of 1–3.5 kHz in gasoline engines [9] when the intake volume is insufficient and matched with a large ignition angle. A study conducted an adaptive generalized S-transform on the cylinder pressure signal of a certain engine with abnormal noise and found an abnormal excitation of 6–8 kHz in the cylinder pressure (noise signal), indicating that combustion noise may occur in the high-frequency range of 6–8 kHz [10].

The current research on combustion noise is focused on idle and acceleration conditions, ignoring the starting conditions. In this study, a series of tests and analyses were conducted to determine the root cause of the abnormal noise in an efficient engine.

2. Overview of Abnormal Noise Issues

A pickup truck produced a strange noise similar to a “click” when starting the engine in a normal temperature environment. However, the first reaction was that the sound was generated by hardware collision during the starting process. Besides, the clutch pedal has a certain vibration sensation. Otherwise, the abnormal noise may lead to poor starting sound quality or even engine malfunction complaints. Multiple driving evaluations found that this is a common problem of the efficient engine. Notably, the abnormal noises did not occur at every start, accounting for about 50% of the number of starts.

3. Troubleshooting and Diagnosis

3.1. Time Frequency Testing and Wavelet Analysis

General signal analysis methods, such as Fourier transform, are only suitable for analyzing steady-state signals since they lose time information after transformation to the frequency domain. Two-dimensional transformation analysis methods with local performance in both time and frequency domains are suitable for non-stationary signals with transient impact characteristics. Wavelet transform can accurately locate the moment of impact and describe the frequency domain distribution of the impact. Besides, it is an applicable and mature time-frequency analysis method for processing transient non-stationary signals.

In this study, the engine was lifted out and fixed on the engine anechoic chamber bench, and an external battery was connected for continuous starting evaluation to better reproduce and test the analysis. The abnormal noise was reproduced, and the frequency of occurrence was about 50% of the starting times.

Microphone and acceleration sensor were installed on the soundproof chamber bench. Notably, the microphone was installed at a distance of 1 m on the intake and exhaust sides of the engine, and the vibration measurement points were arranged on the exhaust side cylinder block and starter housing since the abnormal noise can be recognized in all directions around the engine. Meanwhile, the crankshaft position sensor signal line was led out (60 pulses) to monitor the real-time speed signal of the engine starting process (Figure 1).

Figure 1. Layout of Anechoic Chamber Bench.

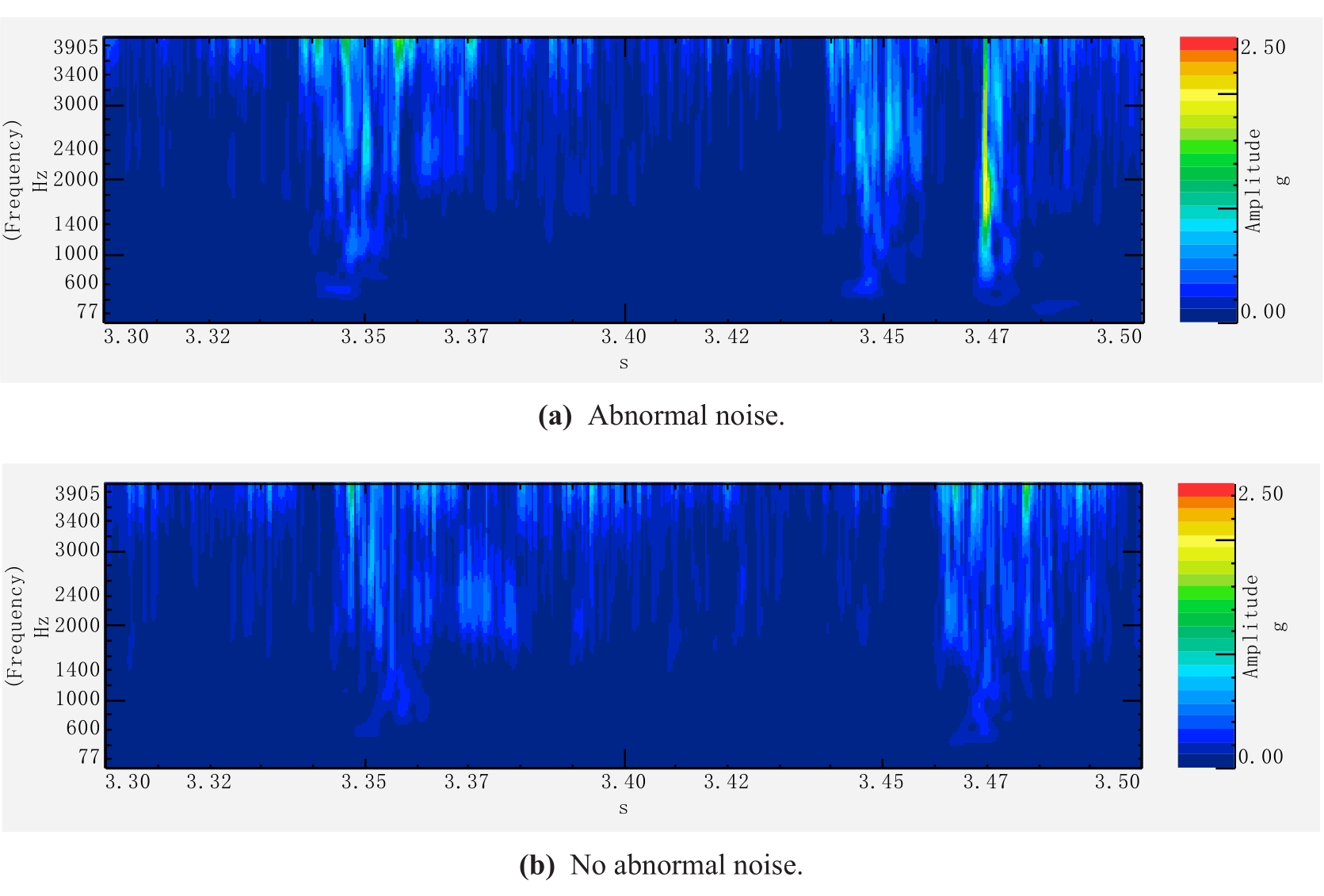

Wavelet analysis of the collected sound and vibration signals was performed using Siemens LMS Test Lab testing and analysis system. The vibration signal processing results of the exhaust side cylinder body with and without abnormal noise are shown in Figure 2. There was a slight additional instantaneous broadband signal of 1–3 kHz in the starting condition at around 3.47 s. The abnormal noise disappeared after filtering and replaying the abnormal noise data through 1–3 kHz, indicating that the noise is 1–3 kHz broadband noise.

Figure 2 Wavelets analysis on exhaust side cylinder block.

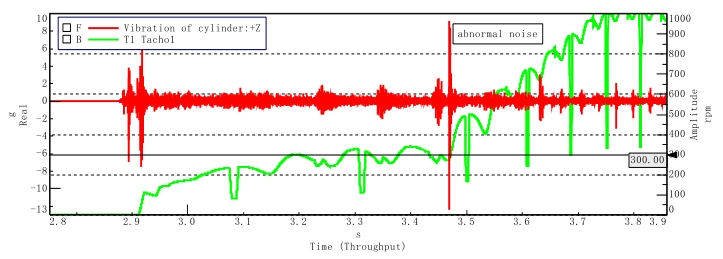

The vibration signal of the cylinder body was filtered on the time domain, with a 1–3 kHz band pass filter, to identify the engine speed corresponding to abnormal noise. The crankshaft position sensor was also subjected to gear compensation and speed increase (Figure 3). The abnormal noise occurred when the engine speed increased to around 300 rpm. The engine speed is in the first stage of significant improvement at 300 rpm, indicating that a cylinder has been injected with fuel and begun to pressurize.

Figure 3. Relationship between abnormal noise occurrence time and rotational speed.

Besides the operation of the engine, the starting condition is only influenced by the starter. The noise caused by the popping and rebound of the starter gear is the maximum noise contribution of the starter. The gear popping noise occurs at the initial operating time, corresponding to the engine speed of 0 rpm, while the rebound noise occurs when the engine speed increases to a certain value and the starter gear exits. The starter control strategy of the vehicle exits the flywheel at 500 rpm. Herein, the abnormal noise was detected at around 300 rpm, ruling out the starter gear pop-out and rebound. This indicates that the abnormal noise may be an internal structural knocking or combustion noise from the engine.

3.2. Cylinder-by-Cylinder Fuel Cut-off Test

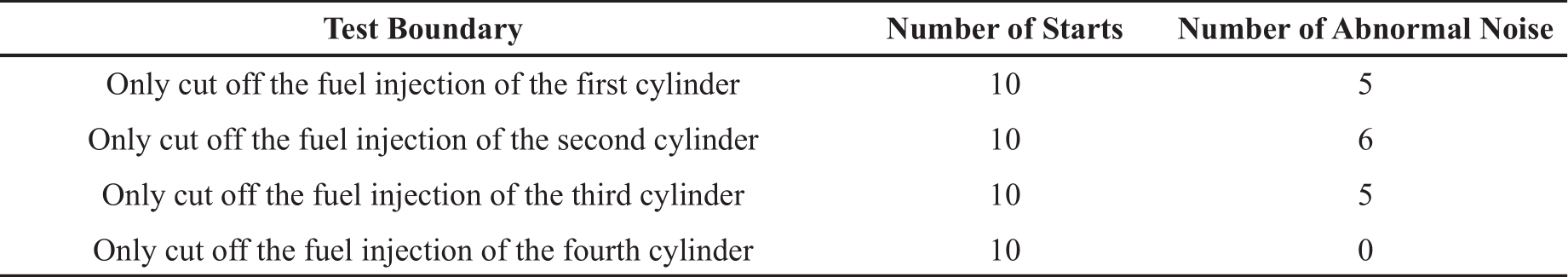

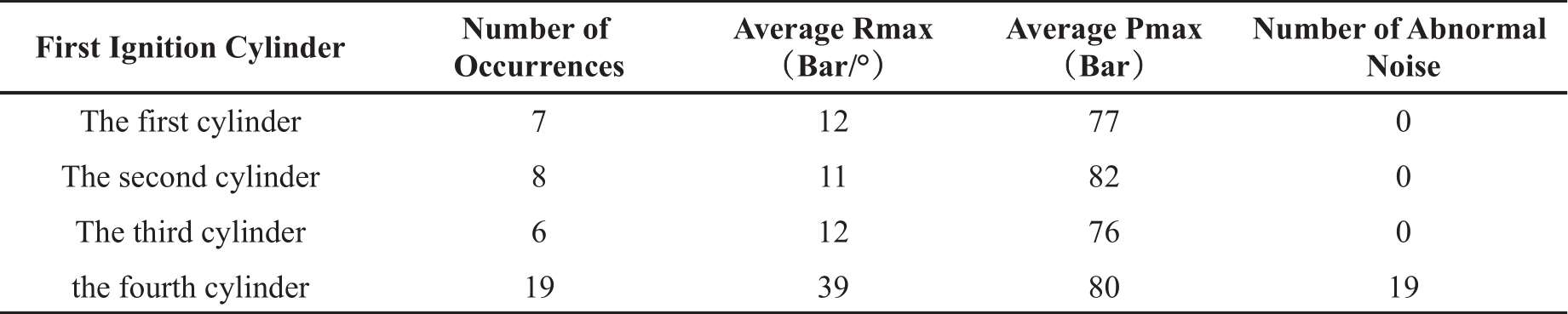

The cylinder-by-cylinder fuel cut-off method is widely used in engine diagnosis. The current ECU could not control fuel injection of a single cylinder. Therefore, fuel injection of cylinders 1–4 was sequentially cut off by pulling out the fuel injection harness one by one for subjective evaluation. Noise evaluations for each cylinder cut-off were conducted for 10 start-ups (Table 1). However, the noise completely disappeared after cutting off the fuel injection in the fourth cylinder, indicating that the noise was related to the combustion in the fourth cylinder.

Table 1. Cylinder-by-cylinder oil cut-off test.

4. Analysis of Combustion Noise

4.1. Analysis of Cylinder Pressure under Starting Conditions

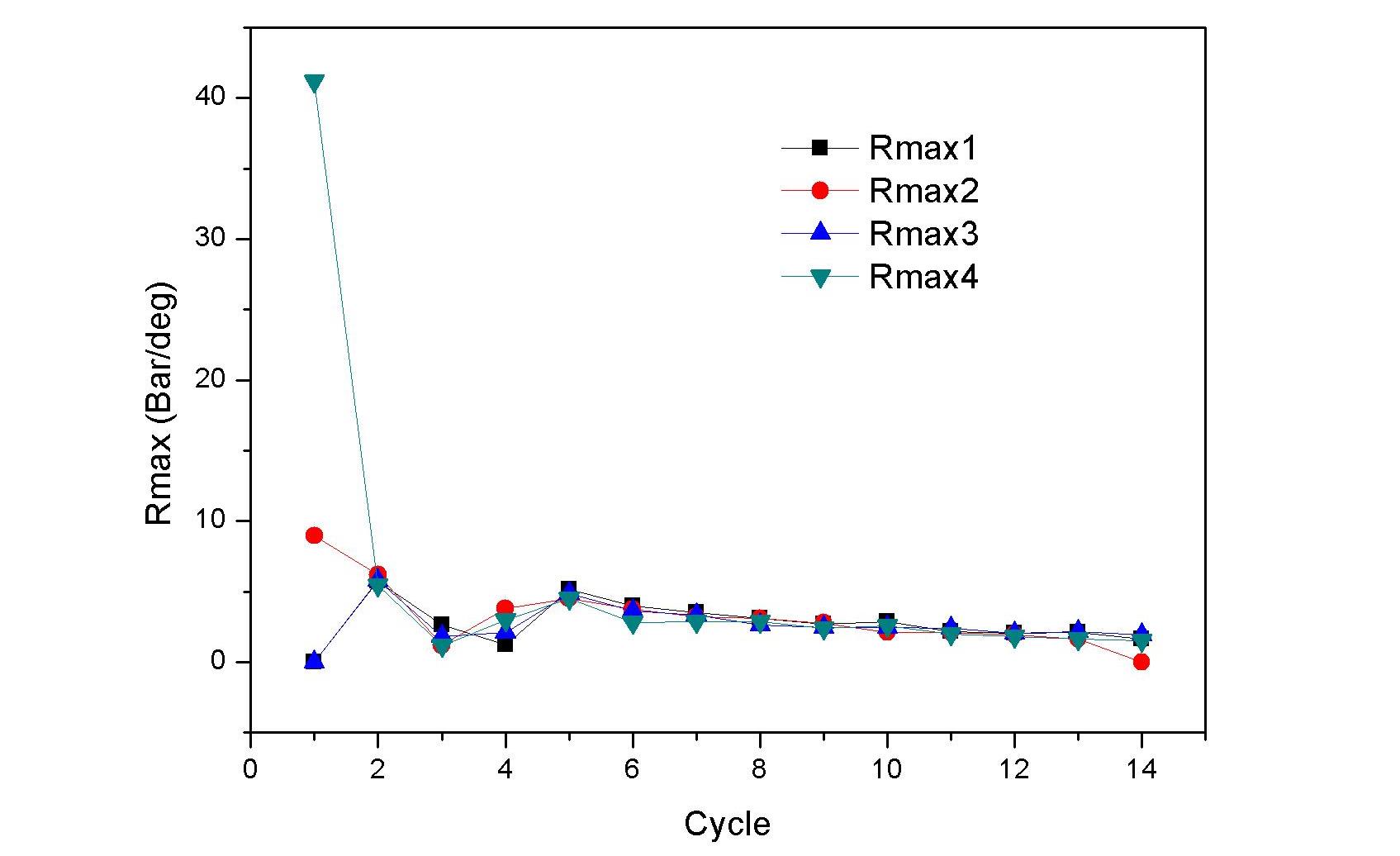

First, glow plug-type cylinder pressure sensors were installed on cylinders 1–4. A Kibox combustion analyzer was then used to test the cylinder pressure characteristics of the diesel engine under starting conditions (40 start-ups). Moreover, 19 abnormal noises occurred during the first successful compression ignition of the fourth cylinder, with a maximum combustion pressure of around 80 Bar, which is equivalent to the combustion pressure of the other three cylinders when they were first compressed. However, the average maximum pressure increase rate of the fourth cylinder reached 39 Bar/° when it was first compressed, and the maximum initial starting pressure increase rate reached 42 Bar/°(Figure 4). Although the other three cylinders were first compressed, the average maximum pressure increase rate did not exceed 12 Bar/°(Table 2).

Figure 4. The maximum pressure increase rate of each cylinder at the time of abnormal noise.

Table 2. Statistics of cylinder pressure data under starting conditions.

The abnormal noise occurred when the fourth cylinder was the first to compress the ignition when starting. The relationship between the intensity of combustion noise and the pressure in the cylinder is shown below:

I,  and

and  represent the intensity of the combustion noise, maximum combustion pressure, and maximum pressure increase rate, respectively. The formula shows that the combustion noise is proportional to the square of the maximum combustion pressure and the maximum pressure increase rate. The maximum combustion pressure of the fourth cylinder was about 80 Bar when the first compression ignition was successful, which is equivalent to the maximum combustion pressure level generated by the first compression ignition of other cylinders. The maximum pressure increase rate of the fourth cylinder was much greater than that of other cylinders. The maximum pressure increase rate of about 39 Bar/° is 1–2 times larger than the pressure of the whole throttle acceleration condition. These findings indicate that the abnormal noise is caused by the abnormal combustion noise caused by the high-pressure rise rate.

represent the intensity of the combustion noise, maximum combustion pressure, and maximum pressure increase rate, respectively. The formula shows that the combustion noise is proportional to the square of the maximum combustion pressure and the maximum pressure increase rate. The maximum combustion pressure of the fourth cylinder was about 80 Bar when the first compression ignition was successful, which is equivalent to the maximum combustion pressure level generated by the first compression ignition of other cylinders. The maximum pressure increase rate of the fourth cylinder was much greater than that of other cylinders. The maximum pressure increase rate of about 39 Bar/° is 1–2 times larger than the pressure of the whole throttle acceleration condition. These findings indicate that the abnormal noise is caused by the abnormal combustion noise caused by the high-pressure rise rate.

4.2. Analysis of Commonly Used Calibration Control Parameters

Combustion in diesel engines is mainly controlled by the relevant parameters of fuel injection, such as rail pressure and fuel injection angle. In this study, the abnormal noise was not improved when rail pressure and fuel injection angle were adjusted. However, a significant reduction in the amount of fuel injection partially improved the abnormal noise. Nonetheless, reducing the amount of fuel injection cannot completely eliminate the abnormal noise. Therefore, further experimental analysis is needed to support the consistency between the actual signal and the calibration command signal.

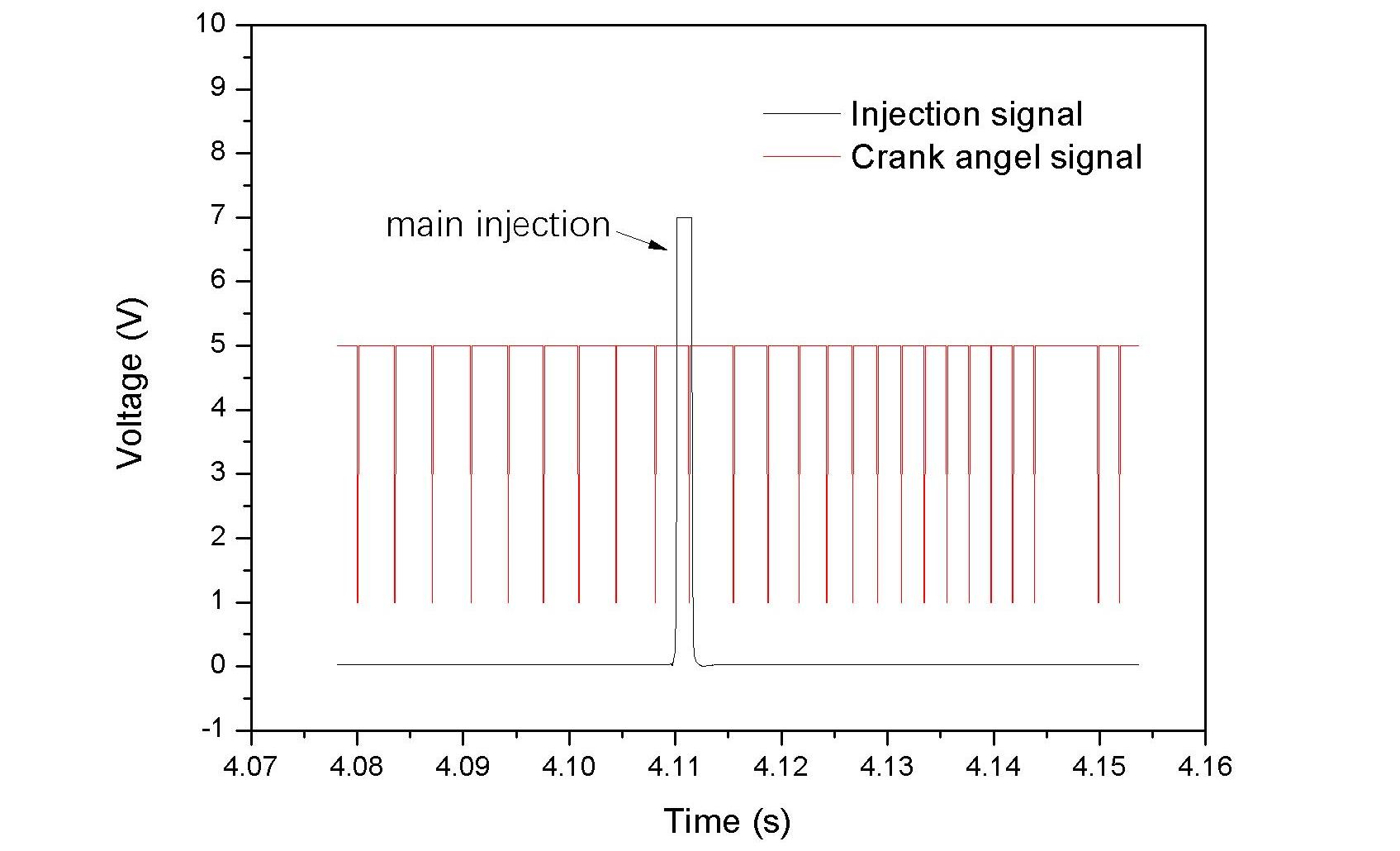

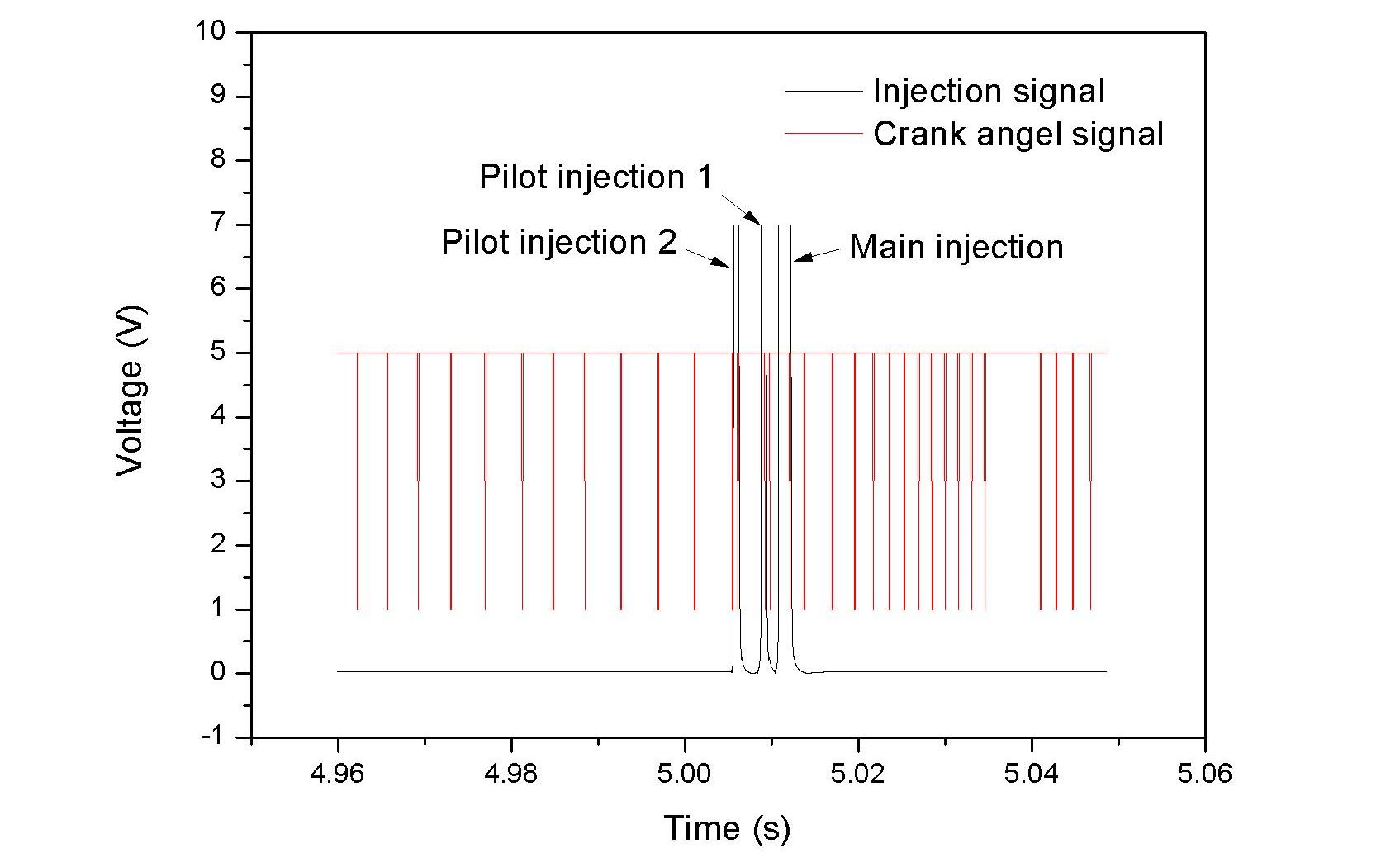

4.3. Initiation of Real Fuel Injection Signal Analysis under Operating Conditions

The fuel injection harness signal of 1–4 cylinders was connected to the LMS data collector through four double-strand signal extension cables (one cable is connected to the fuel injection harness signal line, and the other is connected to the negative electrode). Abnormal noise only occurred when the fourth cylinder was the first to compress ignition. Furthermore, there was only one main injection signal, without any pilot injection signal, when the fourth cylinder was compressed (Figure 5). However, abnormal sound did not occur when the other three cylinders were compressed and ignited first, with two pre-injection signals and one main spray signal.

Figure 5. Fuel injection signal when the fourth cylinder is first pressed and ignited.

The actual fuel injection signal was inconsistent with the control command when the fourth cylinder was the first to compress ignition, with no pilot injection. A higher pressure rise rate was generated due to the large main fuel injection volume under the starting condition, leading to combustion noise. Therefore, further research should assess the underlying software logic to determine the cause of the failure of the pilot injection of the fourth cylinder in the starting condition.

5. Analysis of Underlying Fuel Injection Program

5.1. Condition of Diesel Engine Start

The starter of the truck works with the help of the battery, then the engine is pulled backward to run at 220 rpm. A synchronization signal is obtained after the rail pressure reaches 120 Bar, after which the underlying fuel injection program calculates the pilot injection amount and main injection amount at different set times. The fuel injector sequentially sprays out the pilot 2 injection, the pilot 1 injection, and the main injection before the top dead center.

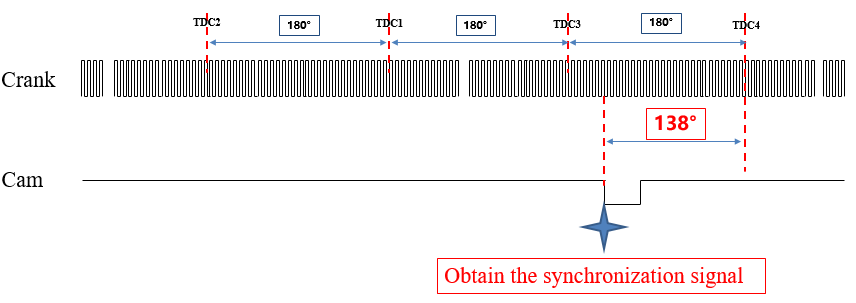

5.2. Synchronization Signal

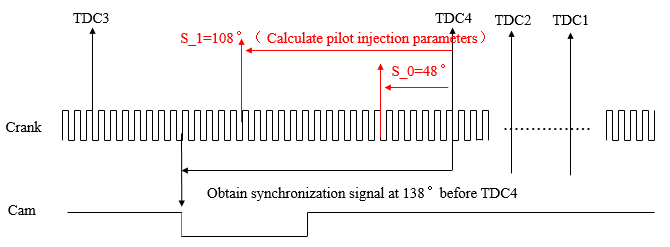

The efficient engine uses a single camshaft signal, and the cam peach tip is used as the synchronous recognition signal for the top dead center. The ECU obtains a synchronization signal every two revolutions. The obtain principle is shown in Figure 6. The synchronization signal was successfully obtained at 138° before the top dead center of the fourth cylinder.

Figure 6. Synchronization signal obtain principle.

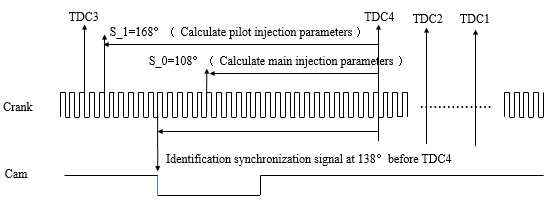

5.3. Underlying Injection Interruption System

The internal programs of the ECU are not always running, indicating that the fuel injection-related programs run periodically. Most fuel injection-related codes need to be executed based on the synchronization signal of the engine.

Therefore, the current fuel injection amount should be determined after identifying synchronization signal. Furthermore, the fuel injector should be controlled to perform fuel injection at the appropriate time. The ECU determines when to run fuel injection-related programs based on the position of the piston, and this moment is called “interruption”.

The current underlying fuel injection interruption system is shown in Figure 7. S_1 represents the starting position for calculating the oil quantity and injection time of pilot 2 injection and pilot 1 injection; S_0 represents the starting point for calculating the main fuel injection quantity and injection time. The pilot injection parameters of the next ignition cylinder were calculated at 168° before the top dead center, while the main injection parameters of the next ignition cylinder were calculated at 108° before the top dead center.

Figure 7. The bottom fuel injection logic.

5.4. Root Cause of Abnormal Noise

These results indicate that the current underlying fuel injection logic is not suitable for efficient engine operation. Specifically, the timing of the pilot injection signal calculation for the fourth cylinder was 168° before TDC4, while the timing of the synchronization signal was 138° before TDC4, which do not meet the pilot injection calculation conditions. Normally, the synchronization signal should be detected before calculating the fuel injection. For the main injection, the calculation time of the fourth cylinder was 108° before TDC4. The main injection can be successfully calculated and smoothly injected before the top dead center after the synchronization signal has been detected. The crankshaft angle must turn past the top dead center position of cylinder 4 if cylinders 2-1-3 are ignited first, successfully obtaining the synchronization signal, to allow smooth injection of the main and pilot injection.

6. Research on Optimization Methods

The current fuel injection interruption logic has achieved targets for idle speed and above, power, emissions, fuel consumption, and NVH while generating combustion noise under the starting condition. Therefore, a separate program was developed for the starting condition (“Start Interrupt Program”) based on the current fuel injection interruption system. In this program, the S_1 position is pushed for pilot injection, and the S_0 position is pushed for main injection (back 60° to the crankshaft angle). The maximum speed for start interruption should be set to 400 rpm since abnormal noise occurred at around 300 rpm. The “start interruption” fuel injection logic is shown in Figure 8. A new fuel injection program takes effect after including the “start interruption” under the starting conditions below 400 rpm. The main and pilot injections of the fourth cylinder can be smoothly achieved after verification (Figure 9). The abnormal noise can then completely disappear. The new “start interruption program” only works under the starting conditions below 400 rpm to optimize the starting performance with no impact on engine performance.

Figure 8. Diagram of the “Start Interrupt” program.

Figure 9. Fuel injection signal when the fourth cylinder is pressurized first after adding the “start interruption” program.

7. Conclusions

(a) Filtering and audio playback analysis showed that the abnormal noise signal is activated at 1–3 kHz. Collection and time-frequency analysis of cylinder pressure and cylinder vibration also confirmed that the abnormal noise is caused by combustion noise. Analysis of real fuel injection signals found that the fourth cylinder only had a main injection signal and no pilot injection signal under starting conditions, further confirming that the abnormal noise is caused by the failure of pre-injection.

(b) Analysis of the underlying fuel injection interruption system revealed that there were unreasonable matches between the current fuel injection program and the single camshaft synchronization signal. The fourth cylinder pilot injection calculation time occurred before the synchronization signal time, resulting in the failure of the pilot injection calculation. However, the main injection successfully achieved the calculations.

(c) A separate “start interruption” program was then developed for the starting condition based on the current fuel injection interruption system. In this system, the pre-injection and main injection calculation times are pushed back 60° to the crankshaft angle at speeds below 400 rpm, ensuring that the synchronization signal of the fourth cylinder is successfully obtained before calculating the pilot injection. The abnormal noise can be completely avoided using this program with no impact on engine performance.

(d) Only a few studies have reported on the combustion noise under engine starting conditions. Therefore, this research provides a basis for further investigation of engine abnormal noise.

Author Contributions: Conceptualization, F.H. and X.Z.; methodology, Y.W. and X.Q.; validation, F.H. and X.W.; investigation, F.H. and X.W.; resources, X.Z. and L.F.; data curation, F.H. and Y.Z.; writing—original draft preparation, F.H.; writing—review and editing, D.L. and Y.D. All authors have read the final version of the manuscript.

Funding: This research received no external funding.

Institutional Review Board Statement: Not applicable.

Informed Consent Statement: Not applicable.

Data Availability Statement: Not applicable.

Conflicts of Interest: The authors declare that they have no conflict of interest.

References

- Guo, E. Analysis of Combustion Noise in Marine Diesel Engines Based on Fuel Injection Strategy. Thesis, Master’s,Harbin Institute of Technology,Harbin,China,2022. https://doi.org/10.27061/d.cnki.ghgdu.2022.001160.

- Zhou, N. Diagnosis Analysis and Simulation Optimization Research on Combustion Noise of Direct Injection Internal Combustion Engines. Thesis, Ph.D.,Zhejiang University,Hangzhou,China,2021. https://doi.org/10.27461/d.cnki.gzjdx.2021.002964.

- He, H. Research on Separation and Prediction Methods of Diesel Engine Combustion Noise. Thesis, Master’s,Tianjin University,Tianjin,China,2021. https://doi.org/10.27356/d.cnki.gtjdu.2021-003612.

- Luo, F.; Zhou, Z.; Zhou, J.; Wu, X.; Tian, Y.; Wu, S. Experimental study on the influence of pre injection parameters and EGR on diesel engine noise. Veh. Eng. 2020, 3, 44–49.

- Jiang, Z. Research on Combustion Noise Control of Diesel Engines Based on Multiple Pre Injections. Thesis, Master’s,Yanshan University,Qinhuangdao,China,2019. https://doi.org/10.27440/dcnki.gysdu.2019.000587.

- Du, H.; Li, J.; Qin, L.; Liu, J. Study on the Influence of Pre injection Parameters on Diesel Engine Combustion Noise. Automob. Tech. 2018, 11, 41–44. https://doi.org/10.19620/j.cnki-1000-3703.20170373.

- Zhang, Q. Research on the Mechanism and Optimization Method of Combustion Noise in Direct Injection Diesel Engines. Thesis, Ph.D.,Zhejiang University,Hangzhou, China, 2017

- Zhang, Q.; Hao, Z.; Zhang, H.; Zheng, K. The influence of common rail pressure on diesel engine noise and sound quality. J. Cent. S. Univ. (Nat. Sci. Ed.) 2016, 47(3), 1017–1023.

- Xiao, J.; Wang, Y.; Zeng, X.; Cao, L. Diagnosis and optimization of combustion noise in Miller cycle gasoline engines. J. Appl. Acoust. 2024, 43, 301–307. Available online: http://kns.cnki.net/kcms/detail/11.2121.O4.20230619.1512.004.html (accessed on 20 February 2024).

- Liu, R.; Hao, Z.; Yan, Y.; Ma, J.; Zheng, X.; Luo, D. Research on Vehicle Abnormal Noise Caused by Gasoline Engine Combustion Noise. Automot. Eng. 2016, 38(10), 1252–1257+1263. https://doi.org/10.19562/j.chinasae.qcgc.2016.10.15.